-

CAS108-21-4

-

Structural formula

C₃H₆O₂

Remove iso-propyl acetate from the exhaust air

What is iso-propyl acetate?

Iso-propyl acetate is a colourless, volatile solvent with a fruity, ethereal odour. It belongs to the ester group and is mainly used in paints, varnishes and printing inks. Thanks to its rapid evaporation and excellent solubility, it is indispensable in many industrial applications.

Origin

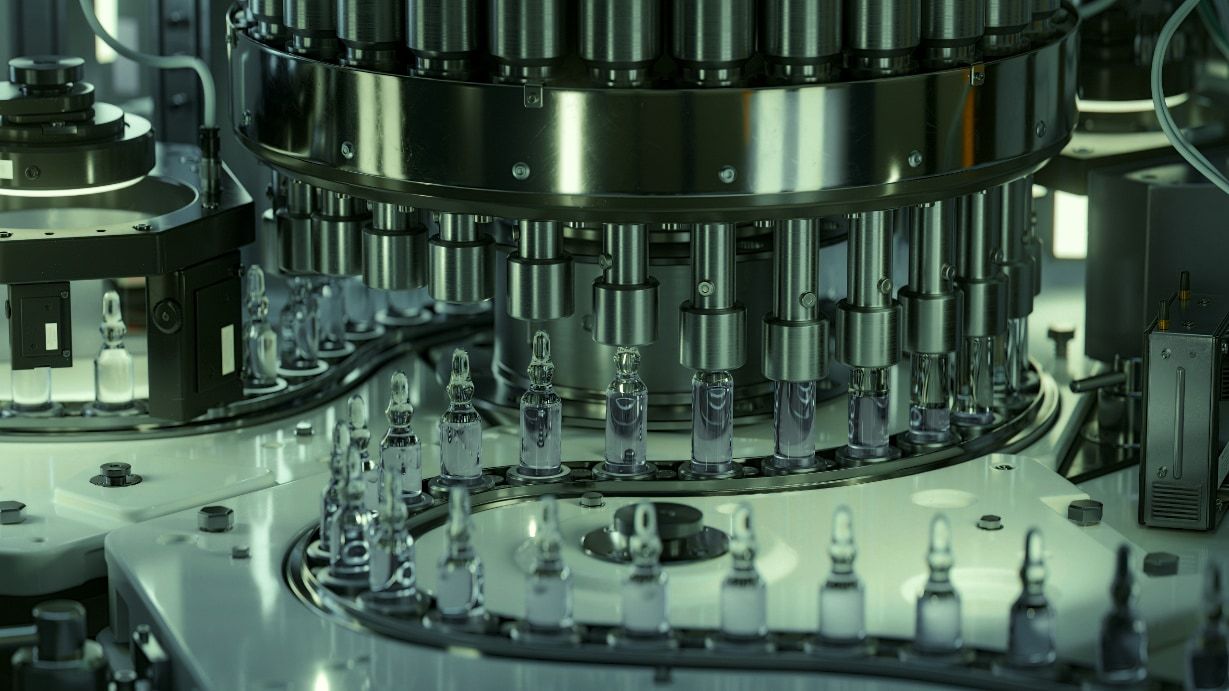

Iso-propyl acetate is produced by the esterification of acetic acid with isopropanol. It is mainly used as a solvent in the paint and coatings industry, in the production of printing inks and adhesives and in the pharmaceutical and cosmetics industries.

Discovery

Iso-propyl acetate is a clear, colourless liquid with a fruity, ethereal odour. It is highly volatile and soluble in water. Contact with iso-propyl acetate may cause eye and skin irritation, and inhalation of the vapours may cause headaches and dizziness.

Limit values

In Germany, the limit values for iso-propyl acetate are regulated by the Technical Instructions on Air Quality Control (TA-Luft) and the occupational exposure limit values (AGW). The OEL for iso-propyl acetate is 200 ppm (parts per million) or 950 mg/m³. These limit values are intended to ensure that the concentrations in the workplace do not cause any damage to health.

Hazards

Health: Iso-propyl acetate can cause eye and skin irritation. Inhalation of the vapours causes headaches, dizziness and nausea. Long-term exposure may affect the central nervous system. Environment: Iso-propyl acetate is biodegradable but may cause water and soil pollution in high concentrations. It is moderately toxic to aquatic organisms. Economic damage: Its flammability poses a fire hazard if handled improperly, which can lead to property damage.

The oxytec Purification Technology

For many organic pollutants, we offer energy-saving and clean technologies for neutralisation, which we combine in multi-stage plants. In order to achieve a reduction below the limit values, not only the dimensioning of the respective purification stage but also the sequence of the technologies is decisive, as they have different physical effects on the molecules. Below we present some of our purification modules.

CWA

Alternative technologies

In addition to our solutions, there are other technologies such as conventional activated carbon filters and simple ventilation systems. However, these often have disadvantages such as high energy consumption, limited cleaning performance, large space requirements, long lead times and high investment costs.

Advantages of the oxytec solution

- Compact design: Small footprint compared to traditional systems

- Low operating costs, therefore fast amortisation

- Environmentally friendly: Minimal environmental impact thanks to innovative technologies

- Efficient iso-propyl acetate reduction: High efficiency thanks to high purification levels with minimal energy consumption