Odourless waste rooms

Fulfil regulations and avoid complaints from residents with exhaust air and recirculated air solutions from oxytec

Odourless waste rooms

Fulfil regulations and avoid complaints from residents with exhaust air and recirculated air solutions from oxytec

Effective odour removal in waste rooms

oxytec is the expert for air and water purification with state-of-the-art UV and plasma technology. Our devices reliably eliminate odours in waste rooms, grease separator rooms and toilet facilities. The advanced plasma technology removes organic contaminants from the air – including odours, germs, allergens and pollutants. Discover our innovative solutions with which you can combat unpleasant odours sustainably – without the use of chemicals.

This is what we offer you:

Effective UV/ozone and NT plasma technology: low-maintenance air purification systems that can also be retrofitted. We can advise you.

Customised solutions: Our systems are suitable for different room sizes – from small rubbish rooms and toilets to complex waste disposal systems.

Sustainable technology: Our systems work without chemicals and without regular filter changes and are characterised by very low energy consumption.

Compliance with regulations: We guarantee compliance with the strictest regulatory requirements in terms of immission control, hygiene and fire protection.

Cost efficiency: Our low-maintenance systems combat odours directly at the source. It is not absolutely necessary to discharge the exhaust air via the roof.

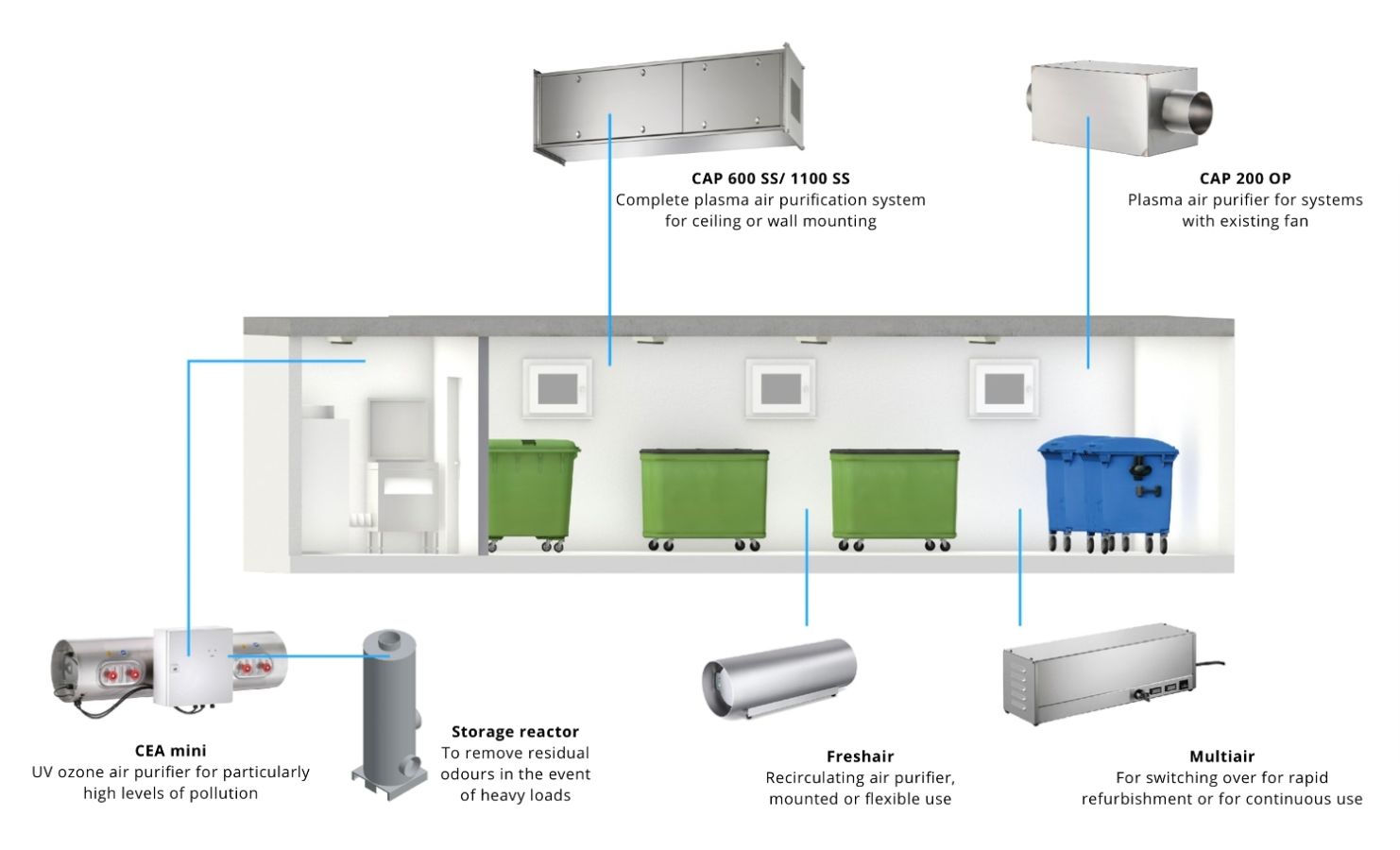

Our solutions for clean air in waste rooms:

CAP mini

The CAP system was specially developed for exhaust air purification in waste rooms. It eliminates odours and germs and enables compliance with legal requirements while reducing operating costs. The combination of pre-filter, plasma unit and activated carbon is suitable for air volumes of up to 1100 m³/h and can be installed in a space-saving manner.

CAP 200 OV

This plasma exhaust air purification system was developed for waste rooms with an existing ventilation system. The device switches on automatically via an integrated pressure monitor. It is suitable for air volumes of up to 200 m³/h and is inserted directly into the exhaust air duct with its DN 160 connection.

Freshair Umluftreinigung

The ideal solution for smaller rooms such as wet waste facilities or toilets. The compact device reduces odours and prevents the formation of germs – a particularly important issue in toilets. The Freshair can be used flexibly or mounted on the wall or ceiling. An on-site exhaust air solution is not required.

Multiair

This recirculating air purifier combines two technologies, UV-C and UV-ozone, and is therefore suitable for both continuous operation and the rapid decontamination of polluted air.

In UV-ozone mode, the air is enriched with ozone, which additionally neutralises the organic pollutants in the air. In UV-C continuous operation, odour pollution is eliminated without ozone emissions.

The device is also available with a timer for automatic switching.

Our special solutions for particular odour nuisances

CEA mini

This cleaning system is designed for strong-smelling and germ-contaminated exhaust air, e.g. from vacuum waste systems. With its UV ozone technology, it effectively eliminates odours in waste sorting and waste rooms, sewage treatment plants (H2S contamination), grease separator rooms, toilets, sludge treatment rooms, wet waste containers and above food waste. With two performance levels, it can be adapted to the individual load.

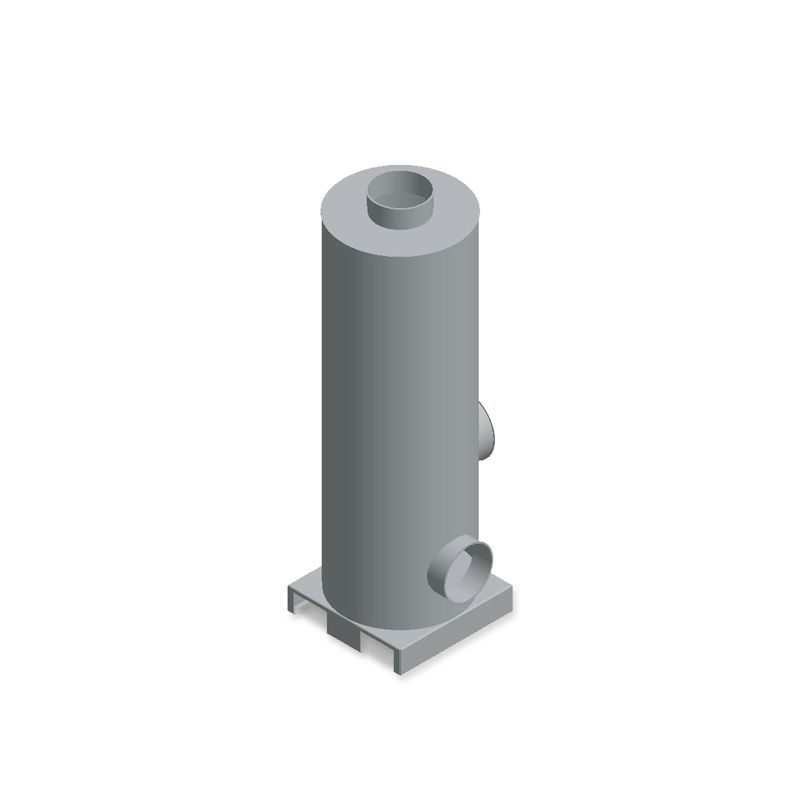

Storage reactor

This storage reactor is designed for post-treatment after UV exhaust air purification. It eliminates any remaining odours with a separation efficiency of 99% in the case of heavily odour-contaminated exhaust air. In order to minimise resistance to the air flow, a specially shaped activated carbon is used, which minimises pressure loss and energy costs. This minimises pressure loss and energy costs.

oxytec can be installed on the ceiling so that they do not restrict the room for manoeuvre.

The oxytec technology

How oxytec plasma works:

The plasma diode generates a microplasma field that breaks down organic molecules and converts them into harmless substances such as carbon dioxide, water and oxygen – the natural components of clean breathing air.

Purification takes place in three stages:

Pre-separation: Coarse contaminants are removed by a pre-filter. This dust filter serves to protect the device and should be replaced regularly.

Plasma stage: Electrical discharges break down odour molecules and carbon compounds into harmless components. The plasma diode is maintenance-free.

Activated carbon catalytic converter: Remaining impurities are retained in the activated carbon filter and further oxidised. The activated carbon filter has a long service life.

How oxytec-UV works

When treating room air with UV-C (without ozone), the UV-C radiation of 253.7 nm effectively destroys microorganisms such as bacteria, mould and yeasts. This process takes place entirely within the device and is harmless to people and animals in the room.

In UV ozone air purification, the exhaust air is channelled through special UV lamps that generate ozone. This reactive oxygen (O3) oxidises organic and fatty substances that cause odours.

UV technology has been used for many years for disinfection in food production and is just as effective for greasy catering exhaust air.

The advantages of both systems:

Odour-free: Plasma technology completely eliminates unpleasant odours.

Energy-efficient: Energy consumption is minimised thanks to the light-based processes.

Sustainable: The systems reduce maintenance requirements and lower operating costs.

Versatile: Ideal for waste rooms, grease separator rooms and toilets.

Fulfil regulations

There are numerous regulations and codes of practice in Germany that regulate the ventilation of waste rooms, among other things. They are mainly found in the state building regulations and in the technical regulations for TA Luft. In essence, there is a ventilation obligation, particularly in apartment blocks, residential complexes and commercial buildings. The aim is to prevent odour pollution and health hazards. A minimum air exchange rate can be derived from DIN 1946-6, which also applies to rubbish rooms. DIN 18012 contains detailed regulations on the planning and design of waste rooms and, among other things, on their ventilation. With oxytec systems, these regulations can often be fulfilled with considerably less effort.

oxytec provides support with planning

Which technology is suitable?

How should the system be dimensioned?

We provide a test system.

We offer to visit reference customers.

We offer solutions for automation.

We provide support with hygiene concepts, e.g. an HACCP concept in food production.